Introduction

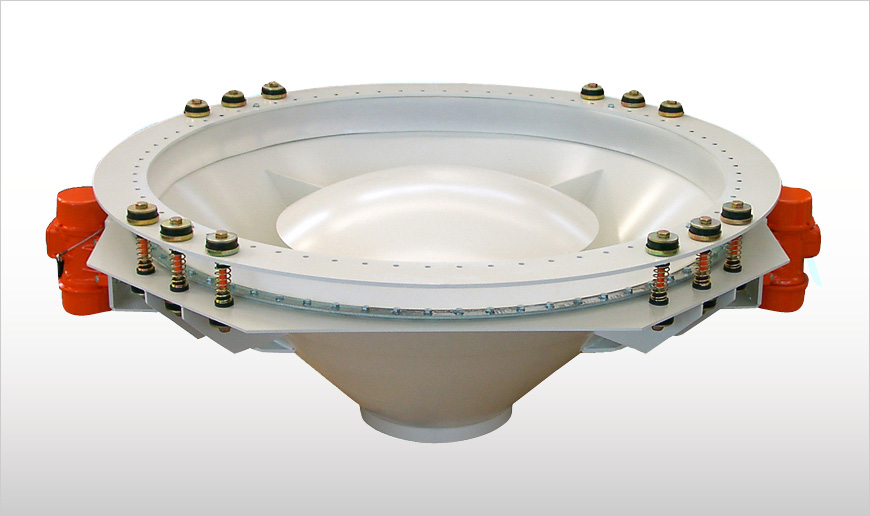

The BA by EXTRAC is the ultimate Bin Activator. Industrially manufactured in large series the BA excels by its seamless cone and its double-flanged, seamless gasket. The BA’s unique design features ensure totally safe operation over time.

Technical Specs

Description

The BA Bin Activator is a device of tapered conical shape that, due to vibration, facilitates material flow from hoppers or silos. It consists of a seamless carbon or stainless steel cone manufactured on a sheet metal lathe, a seamless SINT engineering polymer seal with integrated upper and lower flange, suspensions for connection with the silo cone, as well as one or two electric OLI motovibrators.

Function

To fit the BA Bin Activator, the silo cone has to be shorter than usual, leaving a wide outlet section. A flange supplied before or together with the Bin Activator is welded on the silo outlet cone on site. Special suspensions and a seamless, flanged SINT engineering polymer seal form a flexible connection between silo and Bin Activator. One or two electric OLI motovibrators fitted on the unit generate vibration of the Bin Activator every time the feeding device beneath the silo is started for feeding material. During operation the Bin Activator describes a gyratory movement which is transmitted to the material inside the silo. The result is smooth material flow through the Bin Activator outlet into the connected feeder.

BA Bin Activators are used in various industrial applications to facilitate discharge of powdery or granular materials from a silo or hopper. The use of this equipment ensures optimum feeding of the material according to a “mass flow” condition, thus avoiding bridging or rat holing phenomena.

Features

- Q = 5 ~ 320 m3/h (3 ~ 190 cfm)

- Range: Ø 400mm (16 in) ~ 3,000mm (10 ft)

- Material: carbon steel, 304L / 316L stainless steel

- Robust, compact design

- Range of seals (gaskets) including FDA-approved, food-grade version and high-temperature version

- Wide range of baffle plates in accordance with application

- Low power requirement

- Extra durable suspensions and seal (gasket)

- 70% fewer welds than with traditional bin activators

- Seamless heavy-duty activator cone

Benefits

- Seal with integrated upper and lower flange ensuring safe connection

- No welding seams on cone and seal

- Easy to fit

Options

- Suspensions suitable for installation on aluminium silos

- Vast range of electric motovibrators (see OLI vibrators)

- Additional fluidisation/aeration system

- Outlet spouts with emergency slide gate

- Negative pressure version available

- ATEX Zone 22 version available