Introduction

For large amounts of empty bags to dispose of the COM Bag Compactor is a highly efficient yet economic solution. Bags are compressed to a fraction of their original volume while the workplace is kept perfectly tidy.

Simple, reliable and durable machine

Technical Specs

Description

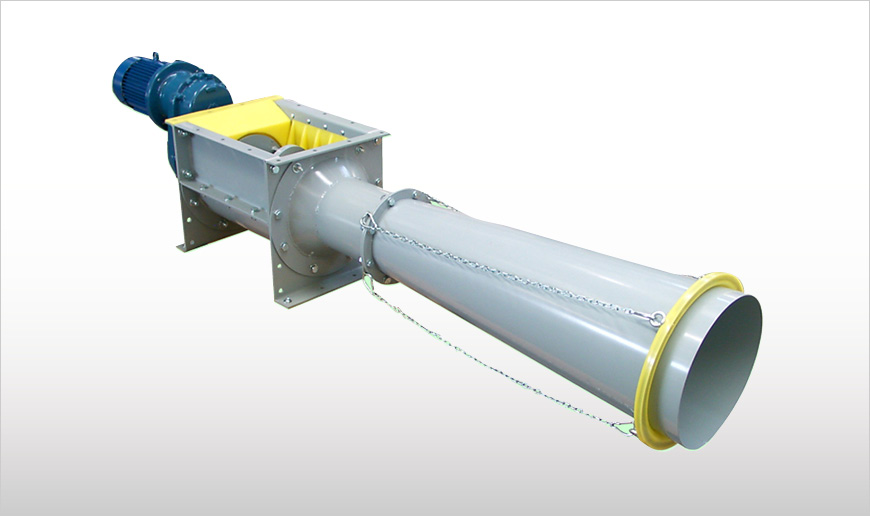

The COM Bag Compactor for broken empty bags consists of a mild steel or 304/316 stainless steel trough with appropriate surface finishing. The U-profile trough is longitudinally split in half to facilitate replacement of the SINT liner that helps introduction and further compression of the broken bags. The Bag Compactor is equipped with a suitable direct drive unit. At the drive end the compactor is equipped with an end plate fixed on the end flange of the trough for assembly of the end bearing complete with flanged shaft coupling for the bag compacting screw. The other trough end is connected with a tapered pipe that facilitates the progress of the compacted broken bags. At the end of this steel pipe a polyethylene tube for disposal of waste bags can be fitted.

Function

The COM Waste Bag Compactor receives entire empty bags or bag fragments from a bag emptying device. It compacts bags to approximately one eighth of their original volume. Waste bags can be easily disposed of by collecting them in a polyethylene hose which has to be periodically cut and sealed.

Features

- Material: carbon steel, 304 L stainless steel

- Complete with adjustable stretch ring for polyethylene hose for disposal of waste bags

- Heavy-duty shaftless compactor spiral with bearing at inlet end

- Direct gear motor drive mounted at inlet end

- Easy access to all parts due to modular design

- Extra heavy-duty shaftless compactor spiral able to handle waste bags of any type without adjustment

- Detachable outlet safeguard in compliance with CE-regulations

- Compactor does not have to be stopped for release of filled polyethylene tube

- SINT engineering polymer liner for optimised bag compression

- ATEX, Zone 22 certification

Benefits

- Reduction of waste disposal costs

- Sturdy and compact

- Competitive price