Introduction

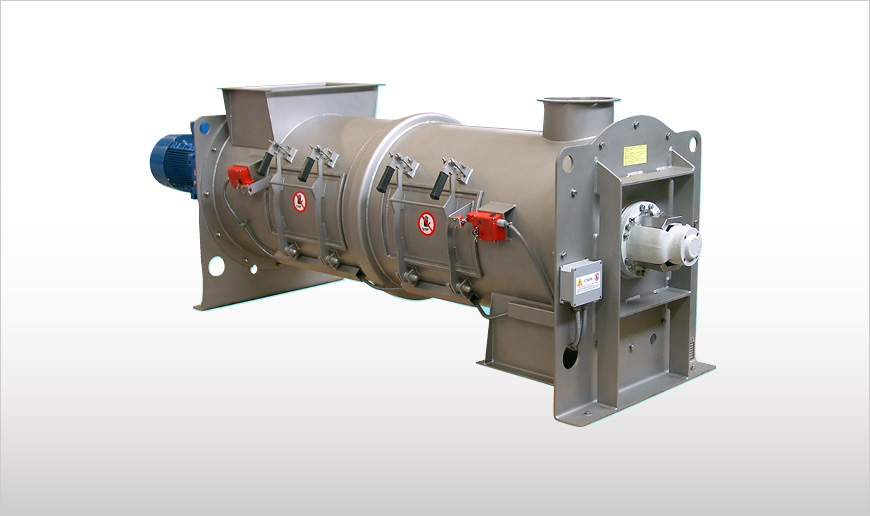

The WAH Continuous Single Shaft Mixer is the ideal machine to obtain highest quality mixtures. Mixing with WAH is quick though gentle. Thousands of mixers supplied in the last three decades by MAP all over the world stand for total reliability and durability.

Consistent quality of the mixture

Profound know-how in mixing applications

Technical Specs

Description

WAH Continuous Horizontal Single Shaft Mixers consist of a cylindrical mixing drum vessel with an inlet at one end of the mixing drum, an outlet at the opposite end and a venting spout, a full material mixing shaft, two drum closing end plates that carry flanged end bearing assemblies complete with integrated air or gas-purged shaft seals, and a drive unit complete with power transmission.

Ploughshares or inclined blade-type shovels rotate as mixing tools in a special arrangement on the mixer shaft inside the drum vessel. The result is a turbulence in the mix that constantly involves all the product particles in the mixing process. The formation of dead spots or slow-movement zones in the mixing drum is prevented ensuring precise mixing. In some cases, to obtain the desired mixing effect, separately driven high-speed choppers can be installed.

Function

Continuous WAH Mixers operate on the principle of a mechanically generated fluid bed. Ploughshare or shovel-shaped mixing tools rotate close to the horizontal, cylindrical drum casing lifting the components to be mixed from the product bed into the open mixing area. The quality of the mixture is achieved before the product reaches the mixer outlet.

Continuous WAH Mixers are suitable for dry bulk solids (powders, granules, short fibres), dry bulk solids + liquids (moistening + granulating), sludge or low-viscosity pastes.

Features

- Capacity: 2 ~ 1,000 m3/h (1.2 to 590 cfm) depending on recipe and mixer configuration

- Possibility of adding up to 20% of liquid

- End bearing assemblies with various types of air or nitrogen-purged shaft seals or grease sealing

- Heavy-duty mixing chamber manufactured from carbon steel, anti-wear steel or 304L / 316L stainless steel

- Stainless steel surface finish: grit silking, mirror polishing, glass bead blasting

- Wide range of mixing tools (ploughshare, toothed ploughshare, blade-type, toothed blade) available with anti-wear coating on request

Benefits

- Maximum mixing homogeneity

- No product damage

- Low maintenance

- Durable

- Power rating adapted to application

- High uptime

- Mixing know-how and test facilities

Options

- Special anti-wear surface treatment (anti-wear liner, wear-resistant coating with easily replaceable tiles, ceramic liner, Teflon® liner, stainless steel mesh)

- High-speed choppers

- Equipment for liquid supply

- Pneumatic sampling device

- Pneumatic control panel

- Heating / cooling mixing chamber jacket

- PT 100 temperature probe on jacketed mixing chamber