Introduction

WAMAIR Dust Collectors are widely recognized as the most versatile compact dust collector range available on the world market for industrial applications. Thanks to various configurations available, WAMAIR has proved to be suitable for virtually all industries.

High filtration efficiency

Reliable, versatile, durable for virtually all applications

Easy installation and maintenance-friendly

Technical Specs

Description

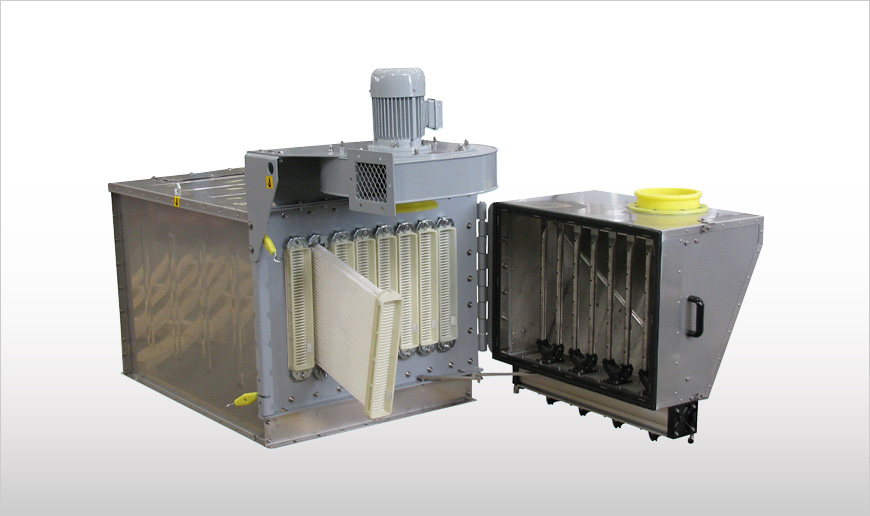

WAMAIR Dust Collectors consist of a polygonal 304 stainless-steel casing, horizontally or vertically inserted pocket-type or high-efficiency POLYPLEAT filter elements.

A compressed air pulse-jet cleaning system is integrated into the easily accessible hinged front door.

WAMAIR Dust Collectors are either built in for venting applications or come as a stand-alone unit with dust collecting hopper.

Versions with an integrated fan are available for suction applications.

Function

WAMAIR Dust Collectors separate dust from the air flow by means of pocket-type or special POLYPLEAT filter elements. Dust drops down after a programmable, automatic compressed air pulse-jet cleaning device integrated into the access door has removed it from the filter elements.

By opening the access door the operator can easily and safely remove the filter elements from the clean air side. The dirty air flow may enter the filter casing from the top inlet flange where heavier particles are subsequently pre-separated while the flow is on its descent. Alternatively, dirty air may enter through the bottom flange, which can be either fixed on a PT-type WAM hopper or on the device to be de-dusted (silo, belt conveyor, bucket elevator, chain conveyor, etc.).

WAMAIR Dust Collectors are configurable for both venting and suction applications.

Features

- Filter surface: 3 ~ 70 m² (32 ~ 755 sq ft)

- Air volume: 250 ~ 9,000 m³/h (147 ~ 5,300 cfm)

- Filter elements: pockets, POLYPLEAT

- Compressed air pulse-jet cleaning system (4 ~ 6 bar)

- Dust temperature range from -20 ~ 80 °C (-4 ~ 176 °F)

- Compact design with favourable volume-filter surface ratio

- Polygonal stainless-steel casing

- Horizontally or vertically mounted filter elements

- Removable rear panel for comfortable inspection of filter media

- Silenced fan integrated into access door with reduced operating noise level

- Multifunctional, multi-voltage electronic control panel

- Designed for outdoor installation

Benefits

- Low emission level due to WAM filter elements and media (BIA/IFA-certified)

- Advanced dust filtration technology

- Reliable, versatile and durable for a variety of dusts and applications

- Compact design and corrosion-free casing

- Quick and safe filter element replacement from clean air side

- Comfortable maintenance height in user-friendly design (no ladders, no scaffolding required)

- Low air consumption with FILCONTROL CONNECT

- Multiple voltages meeting different electric specifications

- EC 1935/2004-certified filter elements and media

- Worldwide after-sales service and spare parts provided by WAM subsidiaries

Options

- Horizontally or vertically mounted filter elements

- Fan or connecting flange to centralised dust suction in front or on top

- Insertable versions available

- 304 / 316 casing and seal frame

- Removable rear panel or with inspection hatch

- Left or right-side door hinges made of mild steel or stainless steel

- Advanced electronic panel with a variety of controls and differential pressure meter (MDPE)

- Weather protection cover with clean air outlet

Accessories

- PT-type dust collecting hopper with flow aid, butterfly valve and bucket

- Choke valve and silencer

- Winter protection for solenoid valves