Introduction

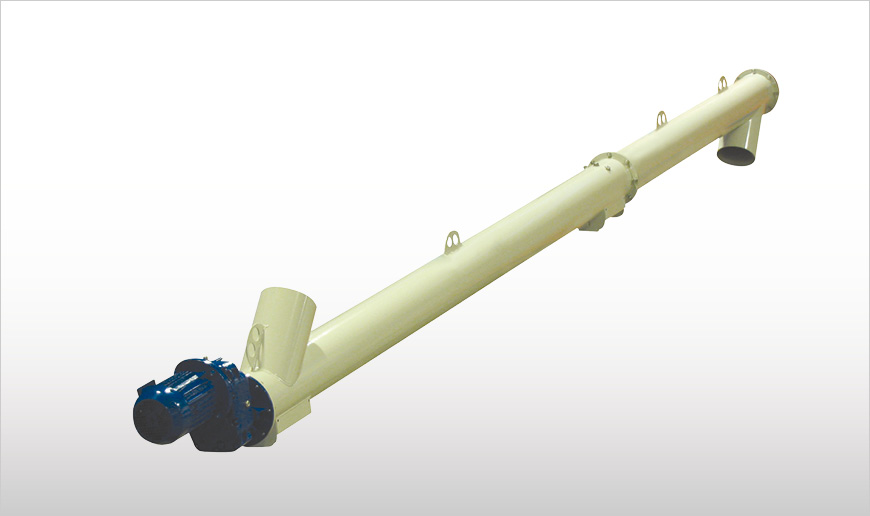

The modular TU Tubular Screw Conveyor and Feeder system is highly versatile offering a variety of standard solutions for handling of powdery or granular materials. Different models of conveyors or feeders are available in applications such as concrete production (for fly-ash, filler dust, silica fume), premixed building materials (dry plasters, sand, cement, additives), glass processing (calcium carbonate, soda, sand, etc.), foundries (sand, bentonite), and many others.

Modular design offering great variety of options suitable for numerous applications

Optimum price-performance ratio

Technical Specs

Description

TU Screw Conveyors and Feeders are manufactured from carbon steel with suitable surface finishing. They consist of a tubular trough equipped with at least one inlet and outlet spout, a welded flange at each tube end, helicoid screw flighting welded on a centre pipe with a coupling bush at each end, two end bearing assemblies complete with self-adjusting shaft seal, a number of intermediate hanger bearings depending on the overall length of the screw conveyor. Furthermore, TU Tubular Screw Conveyors are equipped with a gear motor appropriate for the application.

TU Tubular Screw Conveyors come in a medium heavy-duty design only.

TU Screw Conveyors are available with ATEX, Zone 22 certification.

Function

The modular TU Tubular Screw Conveyor and Feeder system is highly versatile offering a variety of standard solutions for handling of powdery or granular materials. Depending on the characteristics of the material, different models of conveyors or feeders are available in applications such as concrete production (for fly-ash, filler dust, silica fume), premixed building materials (dry plasters, sand, cement, additives), glass processing (calcium carbonate, soda, sand, etc.), foundries (sand, bentonite), and many others.

Features

- 7 outside tube diameters

- Outside tube complete with welded end flanges, one inlet, one outlet, inspection hatch beneath inlet and each intermediate hanger bearing

- Helicoid screw flighting welded on centre pipe

- Powder-coated

- End bearing assemblies complete with self-adjusting shaft seal

- Splined shaft couplings

- Lifting eyelets on each tube section

- Various types of screw flighting

- Compact design and overall dimensions

- Limited number of components and spare parts

- Maintenance-free versions available

Benefits

- Small diameter, great efficiency, high throughput rates

- Modular design offering great variety of options suitable for numerous applications

- Easy installation

- Durable

- Optimum price-performance ratio

Options

- Compact direct drive

- Drive options: direct with or without semi-elastic shaft transmission coupling, chain transmission, belt transmission

- Variable speed drive

- Inlets/outlets with beaded edge or welded flange

- On request: different type end bearings, shaft seals, intermediate hanger bearings, screw (auger) designs

TU SCREW CONVEYORS AND FEEDERS ARE AVAILABLE WITH ATEX, ZONE 22 CERTIFICATION.